Metal cutting

“Impera Group” company carries out metal cutting on professional equipment with high productivity. We use modern metalworking technologies, as a result of which the cutting of metal structures is accurate, fast and inexpensive. We work with individuals and legal entities, focused on wholesale orders, but we also cooperate with retail customers.

Metal cutting methods

There are many methods of metal cutting, the choice of a specific one depends on the material itself and the tasks. Our company uses two main methods:

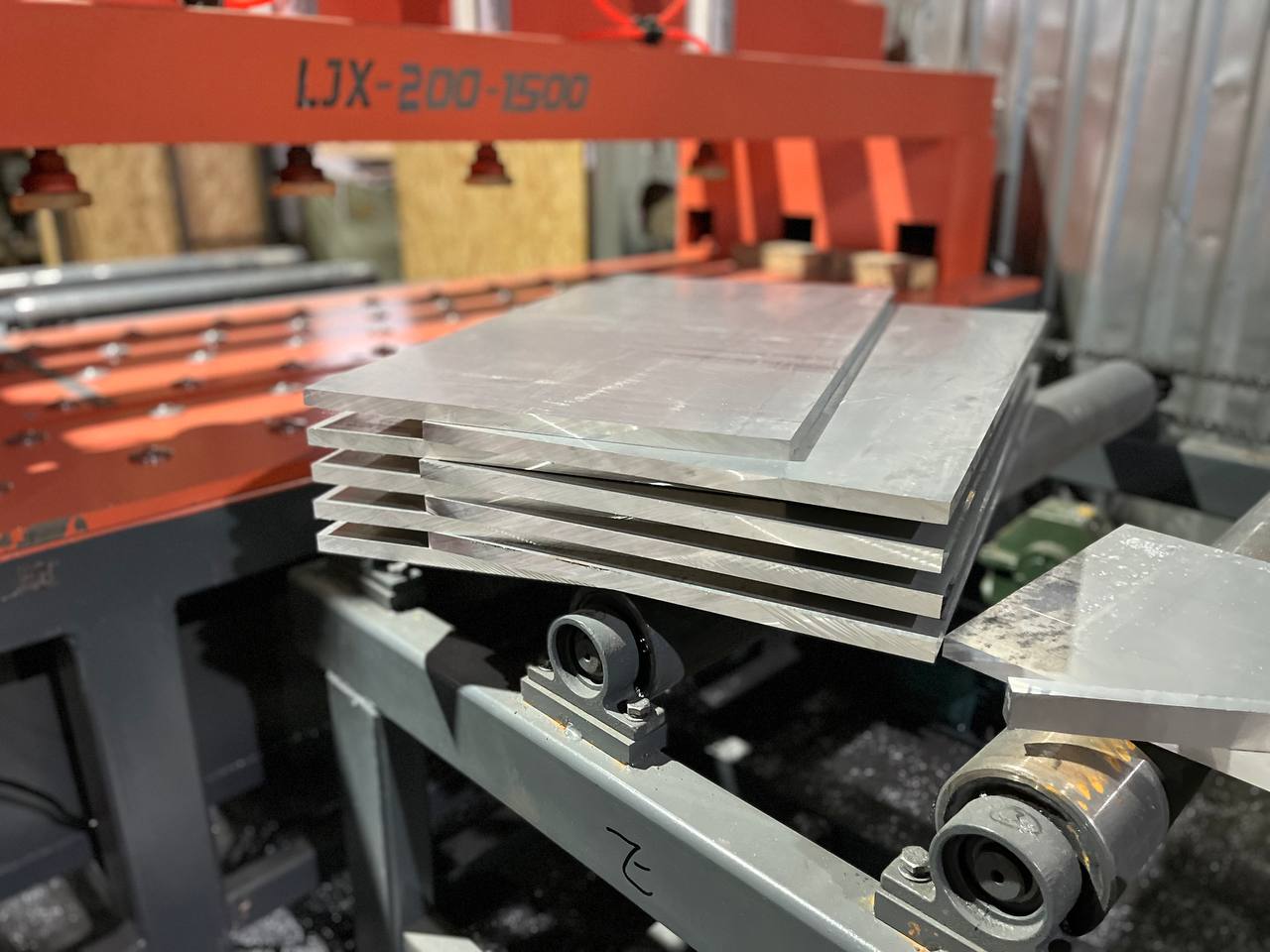

Metal cutting on a longitudinal milling machine. It is used for sawing plates and sheets of metal, mainly aluminum. The permissible thickness of the sprayed sheets/plates is 8-200 mm, the width of the sheet/plate is limited to 1500 mm.

The cost of metal cutting on this equipment is low. Exact fit, high speed, no defects are ensured because we strictly follow the set-up. During mechanical processing, there is no surfacing and other defects characteristic of the thermal cutting method.

Cutting of rolled metal on a band-saw machine. It also provides mechanical cutting of the material, it is used for cutting logs, stainless steel rods, aluminum, special steel and some other metals. The limitation of the diameter of the workpiece is from 8 to 400 mm.

Band saw cutting ensures high accuracy, neat, smooth edges without defects. When processing material loss, the minimum sawing width usually does not exceed 1.5 mm. Cutting on a band-saw machine is suitable for workpieces collected in bundles, for which the price is low. Additional edge processing is not required.

The method of cutting is determined individually. When choosing it, we take into account not only the material, but also its thickness, requirements for the quality of cutting, accuracy, neatness of the edge, etc. We guarantee a quality result.

Company managers will gladly answer your questions, calculate the cost of services and prepare a commercial proposal.

Why do you need metal cutting services?

As a rule, manufacturers of rolled metal offer their products in large sizes – from 3 to 12 m. This is convenient if you have a large enterprise, for example, a construction company, because the larger the element, the more practical it is – minimal waste, it is easier to build different volumes objects

For consumers, such sizes of products create inconvenience during transportation. It is impossible to deliver them with an ordinary truck, and ordering long-distance vans is an additional expense. Metal cutting is designed to minimize costs. We will form segments of the right size that will exactly fit your project. In addition, such a service is relevant when designing and erecting structures of non-standard, complex shape, when the dimensions are determined individually.

We work with various materials: sheet metal, rolled pipes, metal fittings, channels, T-beams, steel strips, etc.

How to order metal cutting?

“Impera Group” has been engaged in the sale and processing of metal for more than 10 years. We have professional equipment at our disposal, and our staff includes high-class specialists with extensive experience. To apply, contact the company’s managers by phone +38 (095) 691 42 62, by e-mail solomka.d@impera.com.ua or fill out the feedback form. Our employee will call you shortly to arrange the details.

Metal cutting prices depend on the specific project, but we can send you a price list on request. Delivery of finished products is carried out in all cities of Ukraine by the carrier you choose, transportation – according to its tariffs. You can pay for our services by bank card online, by bank transfer to our account in the branch, as well as by non-cash payment.

We guarantee the high quality of the work performed. We have our own VTK, whose employees strictly monitor the process and check the result. In addition, our company is certified according to the ISO system.